Product coding is a vital step in the manufacturing process, ensuring traceability, compliance, and brand integrity. However, even a minor mistake can lead to costly recalls, customer dissatisfaction, or production downtime.

In this article, we explore the 5 most common errors in product coding – and share expert tips on how to prevent them.

1. Incomplete or Failed Prints

One of the most frequent issues in product coding is a failed or poor-quality print. This can occur when ink does not adhere properly to the surface, or when the code appears smudged or missing.

How to avoid it:

- Use the correct type of printer and ink for your specific substrate (plastic, glass, metal, cardboard, etc.).

- Keep printheads and nozzles clean and well-maintained.

- Select equipment designed for consistent, high-quality output.

2. Incorrect Printer Configuration

Improper settings such as wrong print distance, speed, or temperature can affect code readability and durability. These configuration errors often result from human mistakes or lack of training.

How to avoid it:

- Choose printers with automatic configuration or user-friendly interfaces.

- Invest in proper training for your operators.

- Standardize settings across production lines when possible.

3. Outdated or Incorrect Information

Printing the wrong batch number, expiration date, or production time can lead to serious problems in traceability and compliance.

How to avoid it:

- Integrate your coding system with a centralized ERP or MES to ensure real-time data updates.

- Use software that allows remote data entry and validation before printing.

4. Lack of Preventive Maintenance

Unexpected printer downtimes are often caused by neglected maintenance. Dirty or worn-out printheads can stop the line and delay orders.

How to avoid it:

- Implement a preventive maintenance plan.

- Use smart coding equipment, such as Linx printers, which alert users when maintenance is due.

- Schedule routine inspections and cleanings to extend printer life.

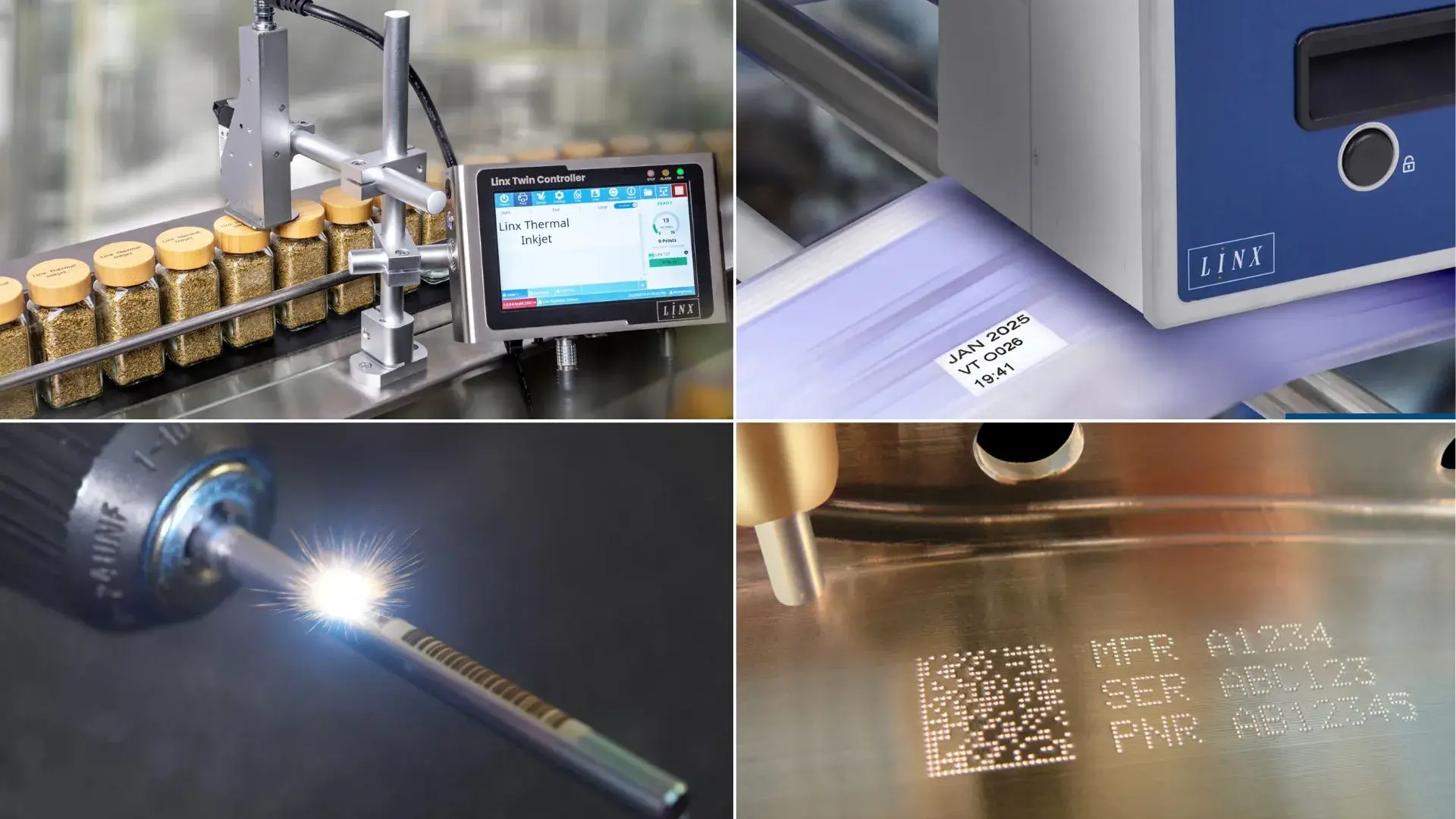

5. Using the Wrong Technology

Each production environment has specific coding needs. A mismatch between printer technology and your production line can cause inefficiencies and poor results.

How to avoid it:

- Consult with coding experts before purchasing equipment.

- For high-speed production lines, Continuous Inkjet (CIJ) is ideal.

- For small batches or simple packaging, Thermal Inkjet (TIJ) may be more cost-effective.

Print with Confidence – Partner with Mark Xtra

At Mark Xtra Coding and Marking Solutions, we help companies across industries implement reliable, efficient, and high-performance coding systems.

Whether you need to upgrade your printer, solve an ongoing issue, or get expert advice before scaling your operation, our team is ready to support your growth.

📞 Contact us today to find the right solution for your production line.