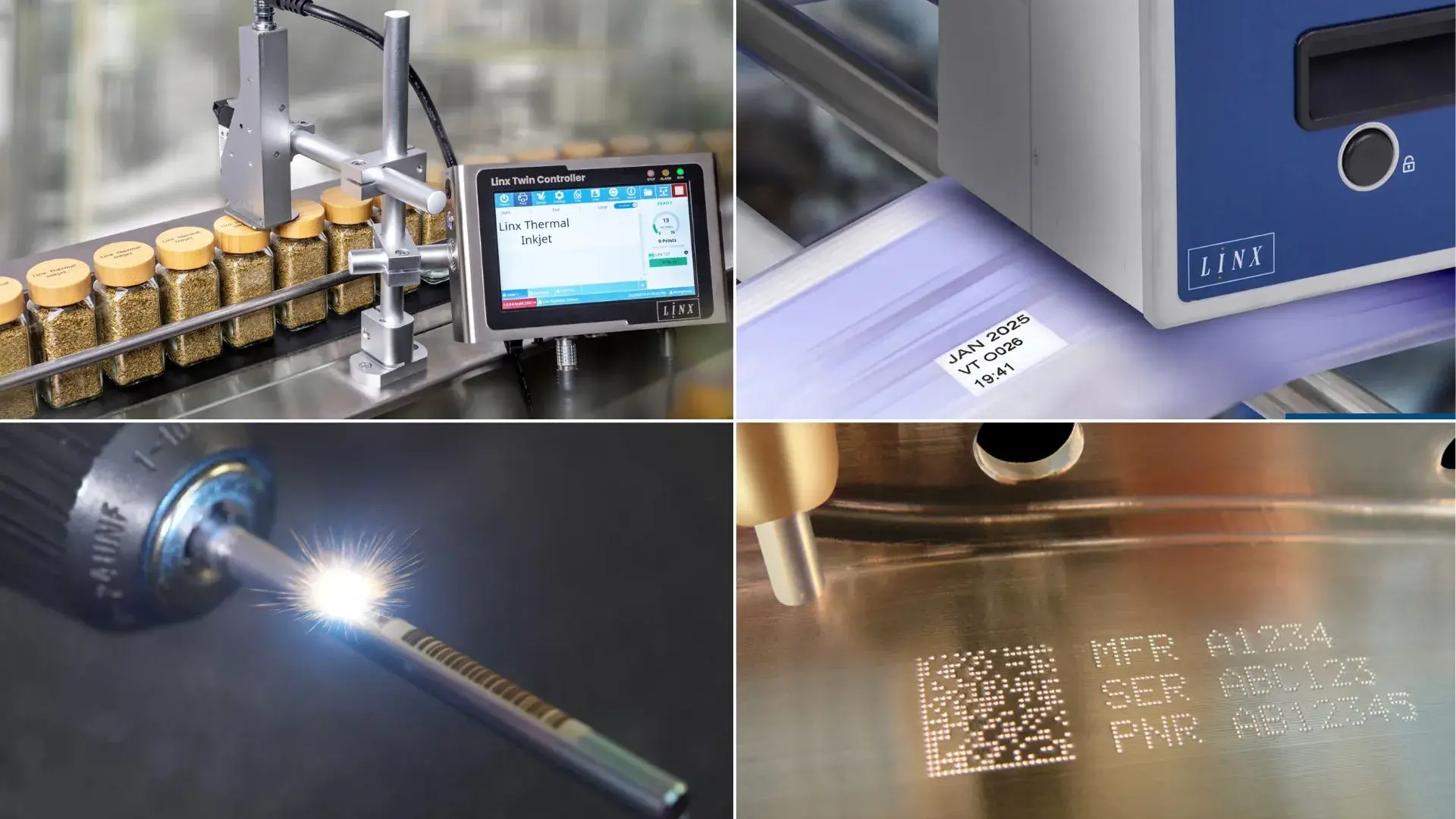

At Mark-Xtra, we provide advanced coding solutions for a wide range of industries. Our laser systems, including CO2, fiber, and UV technologies, deliver durable and high-quality codes for traceability and production data. However, proper safety measures are essential to ensure secure and efficient operations.

Why Choose a Laser System for Coding?

Laser technology offers several advantages over traditional coding methods like inkjet printers or adhesive labels:

- Speed: Capable of keeping up with high-production line speeds.

- High Quality: Prints text, figures, and symbols to meet compliance and traceability standards.

- Eco-Friendly: No need for consumables like inks or labels.

- Permanent Marking: Indelible codes that withstand wear and tear.

The importance of laser safety

Laser coding involves removing particles from the substrate using a highly concentrated light beam. If the beam is misdirected, it can cause accidents and damage equipment. Therefore, implementing safety measures is essential to protect operators and production infrastructure.

Laser classes and safety measures

Lasers are divided into classes from 1 to 4 based on potential hazards. Class 4 lasers pose significant risks to the eyes and skin. However, with proper safety measures, they can be adjusted to operate safely as Class 1.

Key safety considerations:

- Protective housing: Prevents accidental contact with the laser beam. Should be designed based on the laser’s power and wavelength.

- Access prevention: Safety switches that disable the laser when the housing is opened.

- Fume extraction: Filters particles and eliminates odors to keep the production environment clean.

- Protective equipment: Safety goggles specific to each laser type.

- Safety signage: Clear warnings to inform employees about laser presence.

Interesting articles:

- Coding and marking in the pharmaceutical sector

- Importance of Industrial Coding and Marking Printers

Training and supervision

Mark-Xtra recommends appointing a Laser Safety Officer (LSO) responsible for overseeing operations and ensuring staff training. This role is crucial for regular safety inspections and maintaining secure laser operations.

Stay safe with Mark-Xtra

Laser safety doesn’t have to be complex—but it’s essential to get it right. Ensuring safe operations helps protect your staff, extend equipment lifespan, avoid penalties, and maintain smooth production processes.

Mark-Xtra provides advanced laser solutions, full compliance with safety regulations, and expert guidance to keep your coding operations efficient and secure. Contact us for tailored laser solutions and comprehensive safety support!.