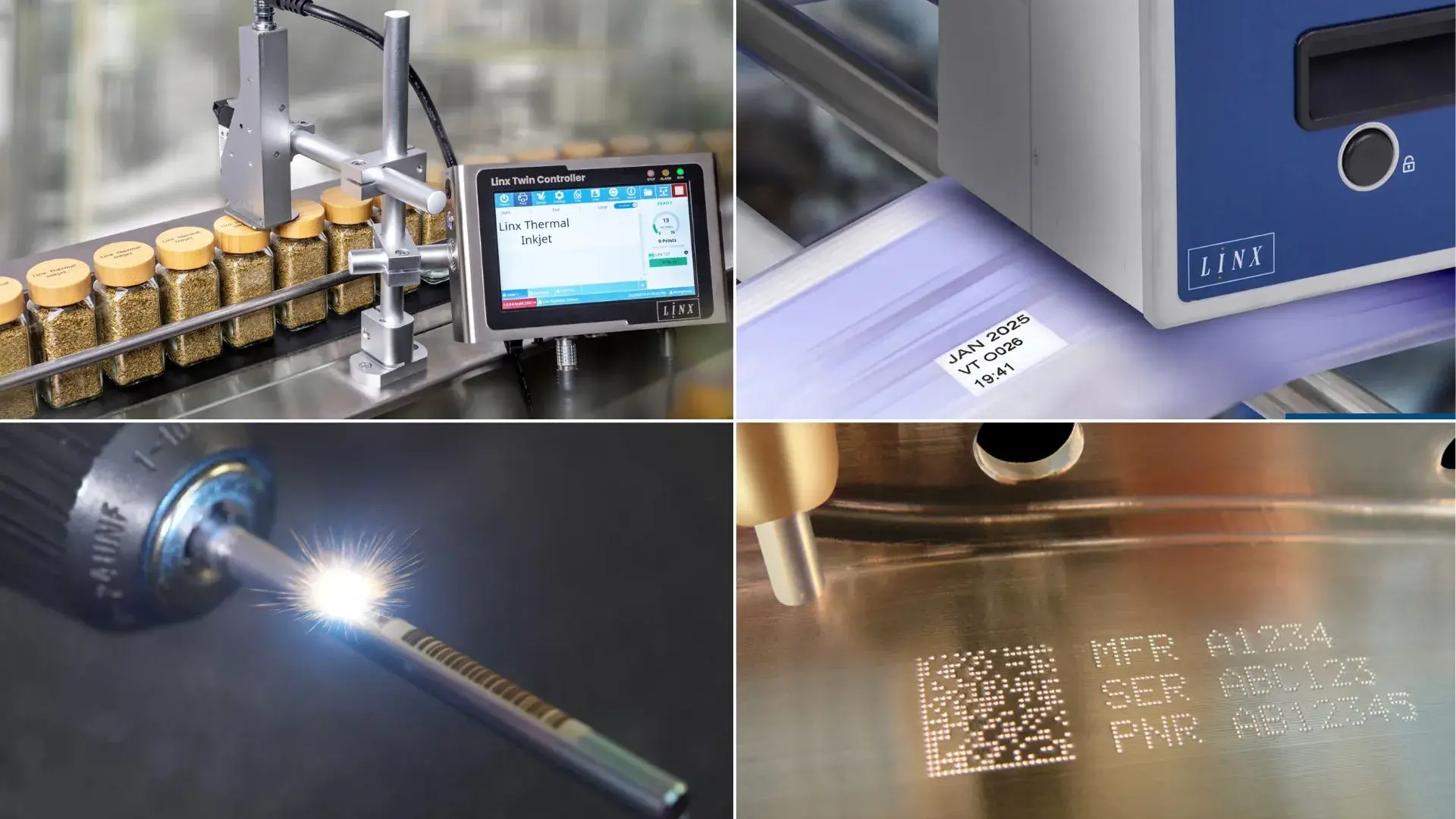

Industrial marking has moved far beyond ink stamps. Modern manufacturers need codes that survive harsh logistics, satisfy traceability rules and keep operating costs low. Linx Laser Coding, offered in Angola by Mark Xtra, achieves all three in one smart investment. Below, you’ll see how Linx laser technology outperforms traditional inkjet systems, why it is a sustainable upgrade for any high‑volume factory, and the concrete gains you can expect once you switch.

What makes Linx Laser Coding different?

1 – Zero Consumables

Ink, solvent and make‑up fluids are history. A Linx laser coder etches information directly onto packaging, eliminating recurring purchases, storage headaches and hazardous‑waste disposal. Over a single year, many plants see consumables savings of 30‑50 %.

2 – High‑Speed Throughput

Whether you run 600 bottles per minute or a blister‑pack line in pharma, Linx laser coders maintain clarity at full conveyor speed. Integrated lenses and advanced beam‑steering achieve output rates that rival—and often exceed—CIJ without sacrificing resolution.

3 – Permanent, Tamper‑Proof Codes

Laser marks are literally part of the substrate. They resist water, oils, heat and abrasion, ensuring lifetime legibility for expiry dates, batch numbers and QR codes. That permanence is essential for brand protection and regulatory traceability.

4 – Minimal Maintenance

With few moving parts and no fluid system, downtime shrinks dramatically. Linx models such as the CSL30 or CSL60 typically require only scheduled lens cleaning and occasional filter changes, giving you OEE improvements of up to 10 %.

5 – Material Versatility

From PET and HDPE bottles to glass jars, aluminium cans, coated cartons and even flexible labels—the same Linx laser adapts via simple focal‑distance or lens adjustments. One coder, multiple SKUs.

Ideal applications across industries

| Sector | Typical Packages | Coding Goals |

|---|---|---|

| Food & Beverage | PET, glass, cans, cartons | Sell‑by, batch, promo codes |

| Pharmaceuticals | Blister packs, vials, cartons | Serialisation, anti‑counterfeit |

| Cosmetics | Tubes, jars, labels | Lot numbers, brand engraving |

| Industrial Goods | Cables, pipes, metal parts | Spec codes, barcodes |

If your business values unbroken traceability and premium shelf appearance, Codificação a Laser Linx is the logical step forward.

Sustainability & Cost‑Reduction benefits

- No chemicals: Slash VOC emissions and improve workplace safety.

- Lower power draw: Modern Linx lasers consume less energy than you expect—often under 500 W.

- Less waste: Forget ink cartridges, solvent containers and associated transport.

- Predictable costs: Operating expenses trend downward once the capital investment is recovered (typically within 12‑18 months).

How Mark-Xtra delivers Linx Laser success

- Line Audit – We analyse speed, products and available space.

- Solution Design – Choose the optimal laser power (10–60 W), lens and beam orientation.

- Installation & Training – Minimal disruption, operators certified in one shift.

- 24/7 Technical Support – Remote diagnostics plus on‑site intervention anywhere in Angola.

- Preventive Maintenance – Scheduled visits that keep uptime above 99 %.

Shifting to Linx Laser Coding means cleaner operations, sharper codes and measurable cost savings. If you’re ready to future‑proof your production while boosting sustainability, Mark Xtra is ready to lead the transition.