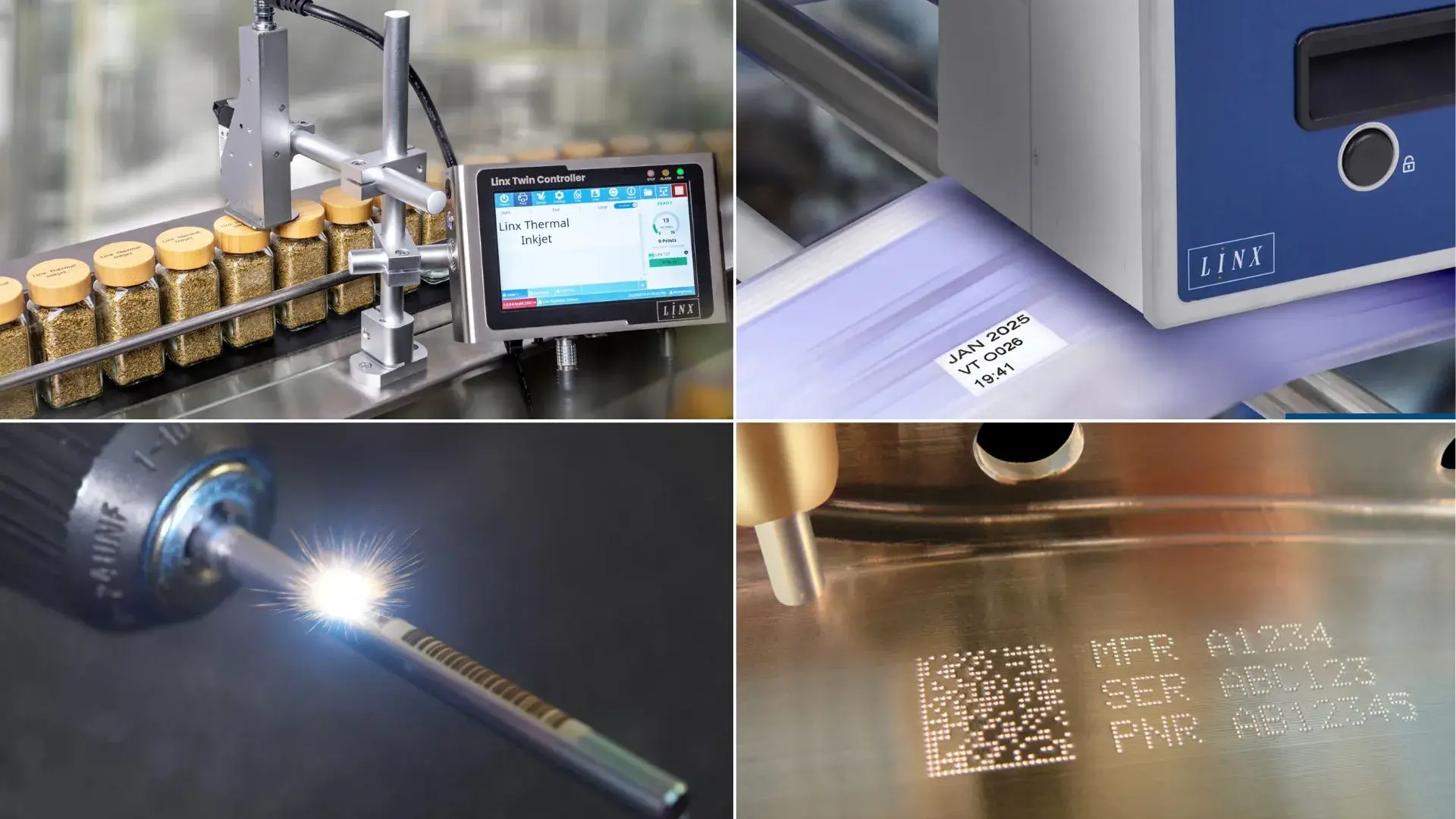

In an industrial environment where resources are limited and the pressure to produce more with less continues to grow, efficiency becomes a decisive factor. Linx offers coding and marking solutions designed to maximize availability, performance, and output quality—making it a strategic ally for any production line.

1. Availability: continuous, uninterrupted operation

With Linx PrinterNet™, printers can be monitored and controlled remotely at any time. This enables:

- Early alerts for faults, low ink levels, or maintenance needs

- Remote diagnostics that reduce the need for on-site visits

- Cloud-based job monitoring and KPI tracking to ensure productivity

The result: reduced downtime and faster changeovers.

2. Performance: Higher speed with fewer interruptions

Linx technology is engineered to keep production running smoothly:

- Self-service intervals of up to 18 months

- Quick-change fluid cartridges that eliminate spills and errors

- Real-time data that improves production planning

This translates into higher speeds, increased output, and fewer stoppages.

3. Output quality: Consistent codes with no rework

Precision in marking is essential to avoid costly mistakes. Linx ensures quality through:

- Intuitive interfaces and WYSIWYG message setup

- Automatic message validation to prevent human errors

- Consistent, high-quality codes that reduce rejects and ensure compliance

Fewer print errors mean less waste and greater reliability.

Linx enhances coding and marking efficiency through three pillars:

Maximum availability, optimized performance, and impeccable quality.

The result is a smoother, more profitable, and more reliable production process.