In industries like pharmaceuticals, cosmetics, food, and healthcare, the accuracy of product information is more than a regulatory requirement—it’s a matter of consumer safety. Choosing permanent coding in these sectors is not just strategic; it’s essential.

Why is permanent coding crucial?

Sensitive products require an extra layer of control and traceability. Details such as expiration dates, batch numbers, and tracking codes must be clear, legible, and most importantly, tamper-proof. Any attempt to erase or alter this information can compromise public health and the brand’s credibility.

Key Benefits of Permanent Coding

1. Enhanced protection against fraud

Permanent codes—especially those created through laser coding—are highly resistant to tampering. This makes it difficult for illegal practices like changing expiration dates or falsifying batch numbers to occur, particularly in informal or unregulated markets.

2. Durability under extreme conditions

Products exposed to temperature variations, moisture, or friction—such as pharmaceuticals, cosmetics, or chilled foods—require markings that withstand time and environmental stress.

3. Regulatory compliance

Health authorities and regulatory agencies demand high standards of traceability. Permanent codes ensure that critical information remains visible throughout the product’s life cycle.

4. Brand protection and consumer trust

Durable, high-quality coding reflects a brand’s commitment to safety. Clear and reliable information gives consumers peace of mind.

5. Reduced operational risks

Faded or illegible codes can result in returns, fines, or even product recalls. With permanent coding, those risks are drastically minimized.

Where is permanent coding most beneficial?

- Pharmaceuticals: tablets, vials, ampoules

- Cosmetics and personal care: plastic and metal packaging

- Perishable foods: dairy, meat, frozen products

- Medical supplies: syringes, sterile instruments, hospital kits

How Linx technology supports this need

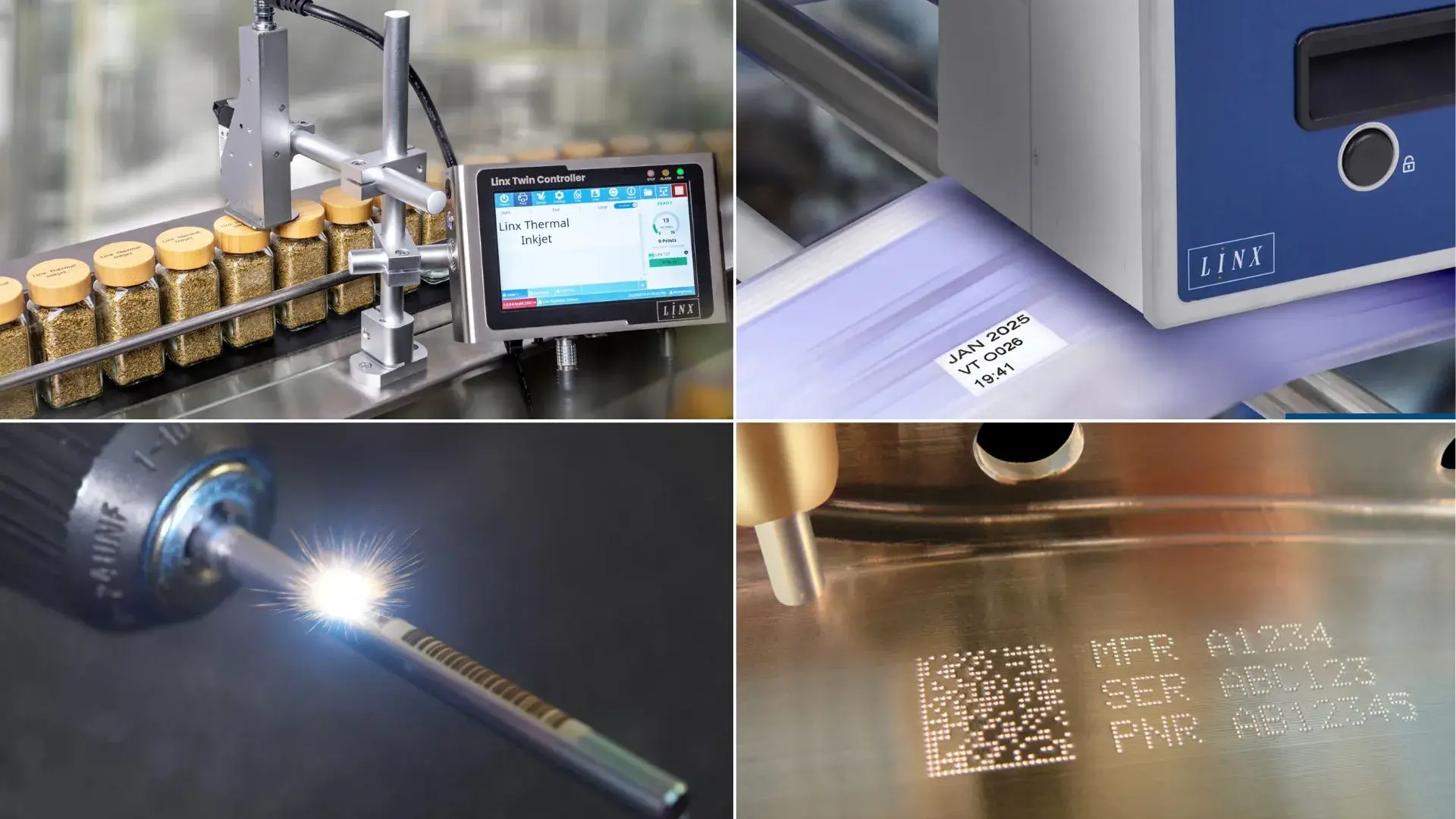

At Mark-Xtra, we provide Linx laser coding solutions that meet the highest standards of quality and durability. With permanent marking and no consumables, Linx printers are ideal for demanding environments and high-performance production lines.

Permanent coding on sensitive products is not just about regulatory compliance—it’s a competitive advantage. It adds value to your brand, builds consumer trust, and helps prevent potential risks.

Invest in safety, traceability, and innovation with Mark-Xtra solutions.