In today’s fast-paced industrial environment, the need for precision, speed, and efficiency is higher than ever. One area where this is particularly evident is in industrial coding processes. Whether marking products for traceability, compliance, or branding, automation plays a crucial role in transforming traditional coding processes. By integrating automation into industrial coding, companies can optimize their operations and maintain high-quality standards.

Understanding industrial coding processes

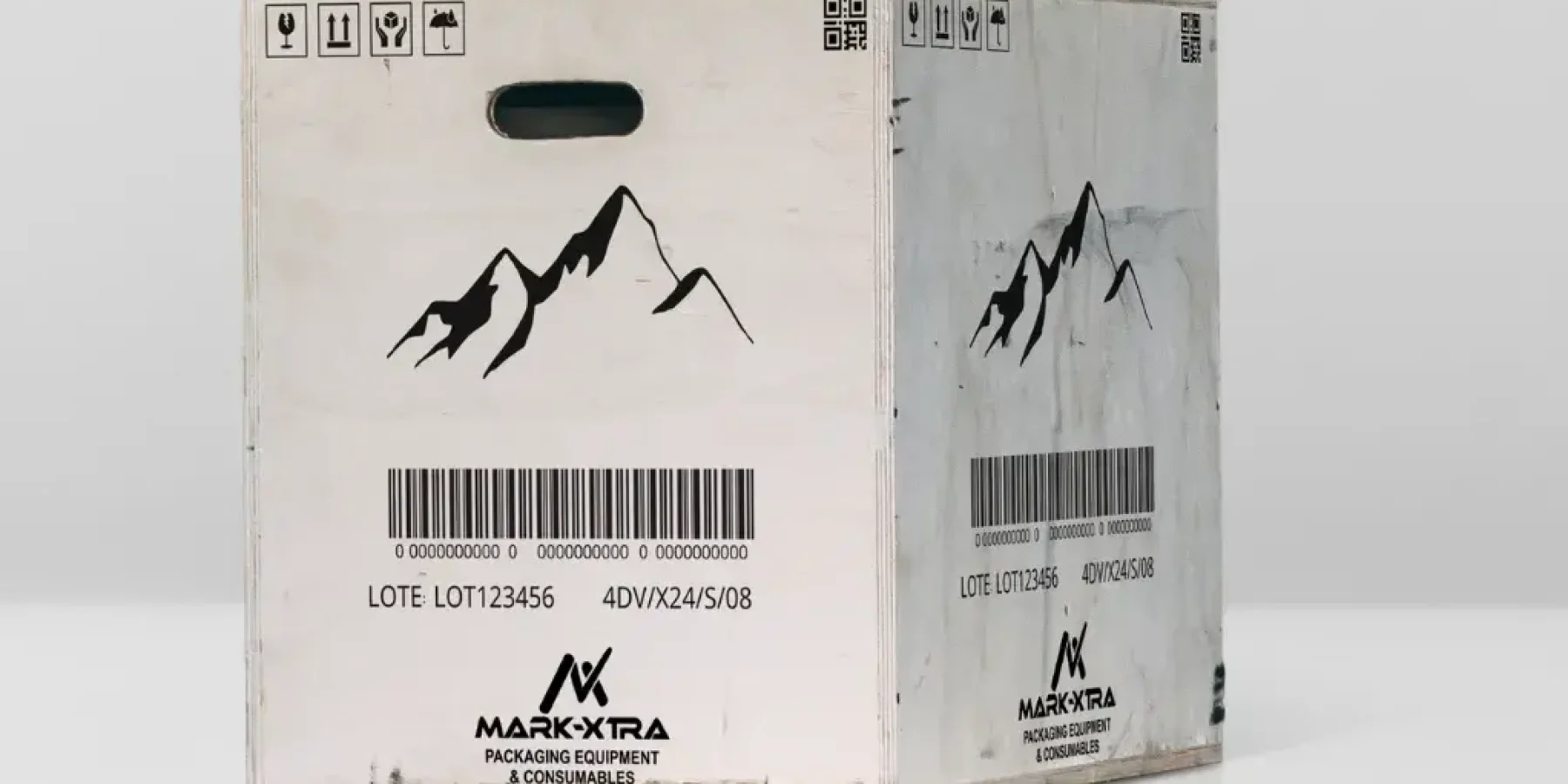

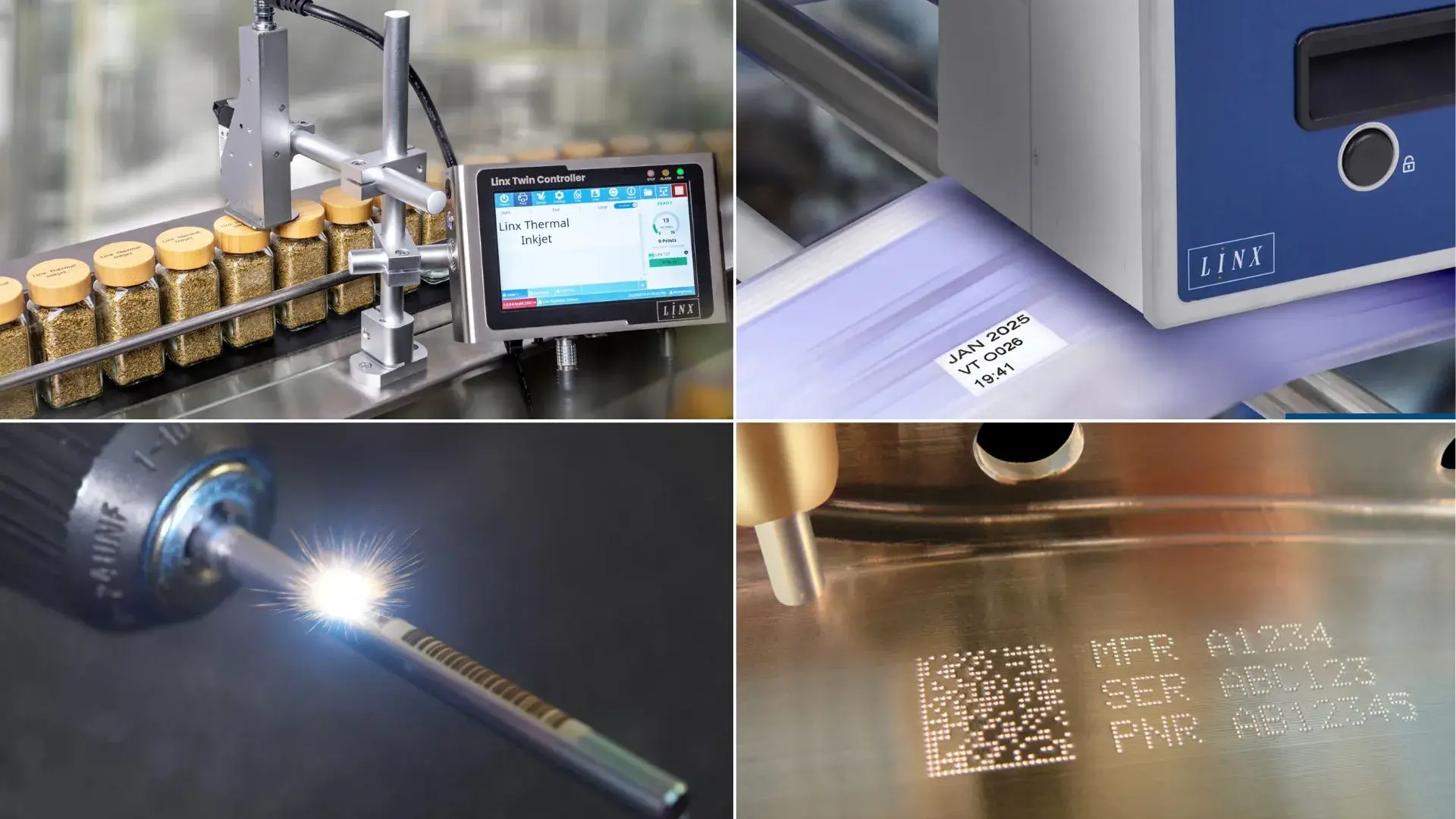

Before diving into the benefits of automation, it’s essential to understand what industrial coding processes entail. Industrial coding refers to the use of machines to print or mark unique identifiers, batch numbers, expiration dates, QR codes, and other essential information onto products or packaging during the manufacturing process. This information is critical for traceability, quality control, regulatory compliance, and branding.

As industries grow and demand increases, the need for faster, more accurate, and more reliable coding systems becomes essential. Manual coding, or using outdated manual systems, introduces the risk of errors, inefficiencies, and production downtime. This is where automation comes into play, offering a solution that can enhance productivity and accuracy significantly.

Benefits:

Automation in coding provides several advantages that directly impact production efficiency, product quality, and cost-effectiveness.

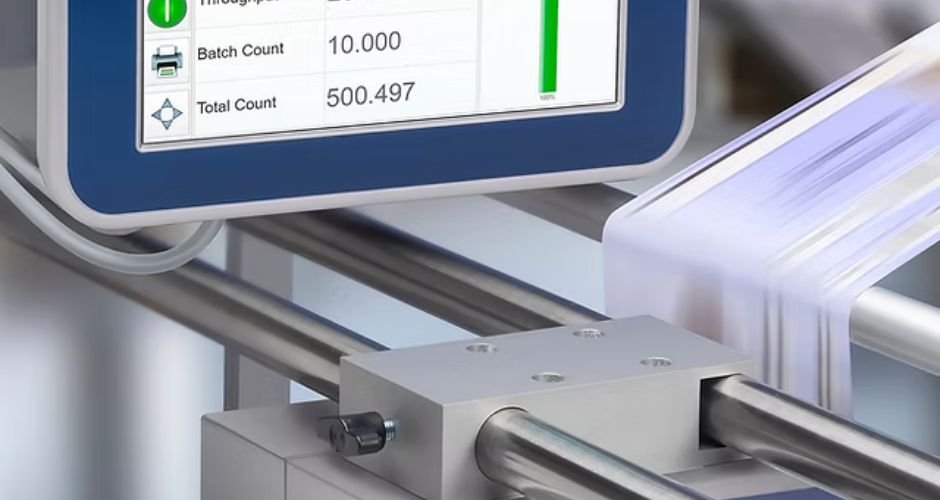

- Enhanced Productivity and Efficiency: Automated systems work faster than manual methods, enabling higher production output. With automated coding, companies can meet demand without sacrificing quality.

- Consistent and Accurate Marking: Automation eliminates the risk of human error, ensuring precise and consistent marks across every product. This level of accuracy is essential, especially in industries where compliance and traceability are critical, such as pharmaceuticals and food.

- Reduced Operational Costs: By reducing the need for manual labor, automated systems lower labor costs and minimize the occurrence of errors or rework. This translates into reduced operational expenses and improved profitability.

- Improved Traceability and Compliance: Automated systems ensure that each product is marked according to industry standards and regulations, facilitating easier tracking and reporting, especially for sectors like healthcare and food safety.

- Adaptability to Different Materials: Whether marking on metal, plastic, glass, or paper, automated coding systems can easily adapt to different substrates, offering flexibility across diverse production lines.

- Scalability for Future Growth: As your production increases, automation allows you to scale up easily without significant investments in new staff or equipment.

- Sustainability: Automated systems reduce waste by optimizing resource use, resulting in a more environmentally friendly process.

Conclusion

In conclusion, automation in industrial coding processes offers significant benefits, including increased efficiency, enhanced accuracy, and lower operational costs. It provides businesses with the tools they need to improve traceability, maintain compliance, and scale production.

If you are looking to take your industrial coding to the next level, Mark Xtra offers advanced, customizable solutions to meet your specific needs. Contact us today to discover how our automated systems can streamline your production and help your business stay competitive.