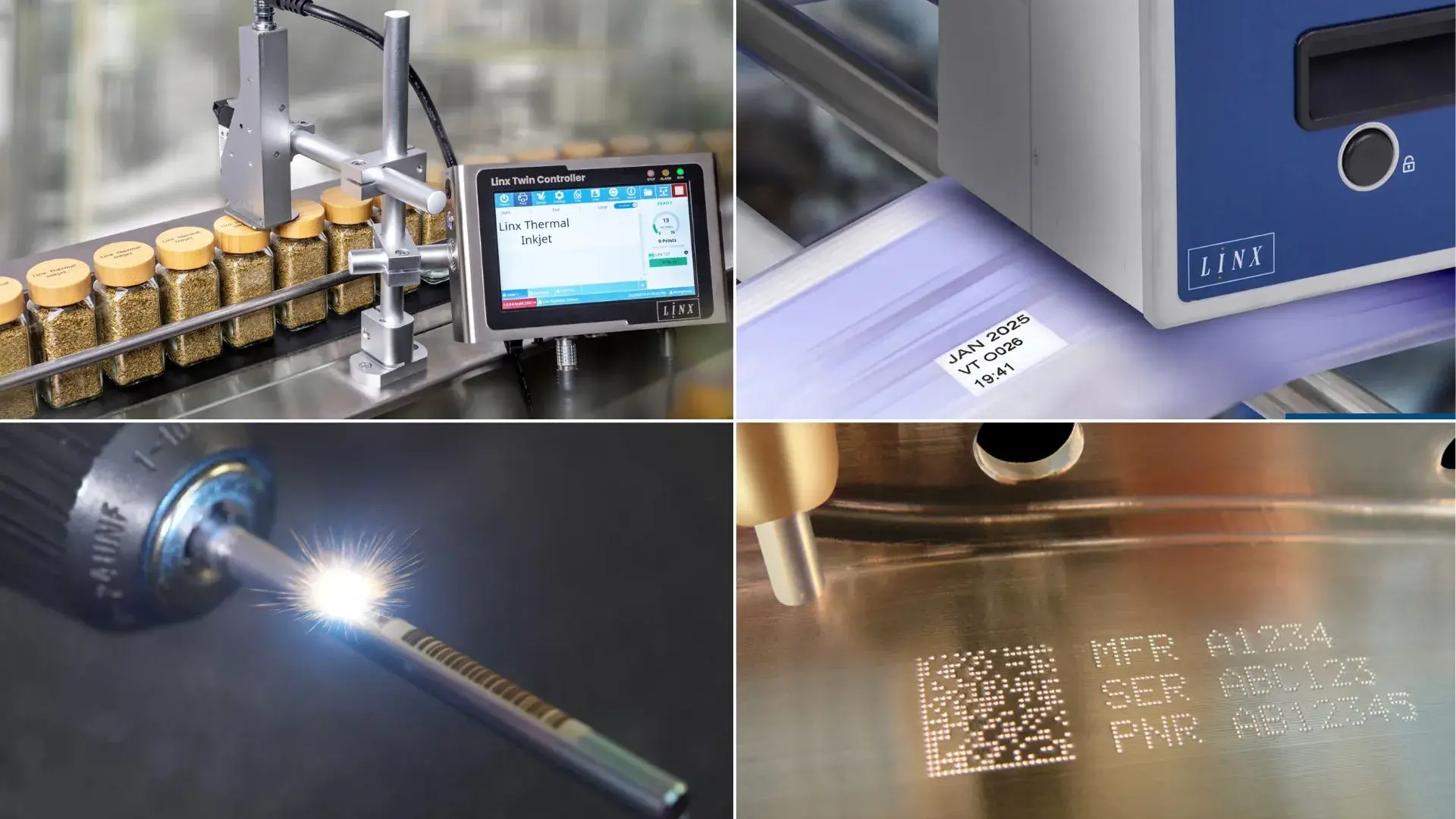

In today’s competitive industrial environment, manufacturers must choose coding solutions that ensure traceability, compliance, and cost-efficiency. Two of the most widely used technologies in product marking are Continuous Inkjet (CIJ) and Laser Coding.

But when it comes to your production line, which one offers the best value and performance?

This article will help you compare both systems to make an informed decision based on your business needs.

What Is CIJ (Continuous Inkjet)?

CIJ technology works by continuously ejecting ink through a pressurized nozzle to form characters or codes on various surfaces. It’s one of the most popular choices in industrial coding due to its speed, versatility, and affordability.

Main Advantages of CIJ:

- High-speed marking for fast production lines

- Suitable for both porous and non-porous materials (plastics, glass, metals, paper)

- Flexible message changes with minimal downtime

- Lower initial investment compared to laser systems

Best suited for: food & beverage, personal care, household goods, and general manufacturing.

What Is Laser Coding?

Laser coding systems use concentrated beams of light to permanently etch or engrave codes directly onto product surfaces. This method eliminates the need for consumables and provides high-contrast, tamper-resistant marks.

Main Advantages of Laser Coding:

- Zero consumables → lower long-term operational costs

- Permanent, high-quality marking resistant to wear and abrasion

- Minimal maintenance required

- Eco-friendly and highly sustainable

- Consistent results, even in harsh production environments

Best suited for: pharmaceuticals, beverages, cosmetics, electronics, and high-value products.

CIJ vs. Laser Coding – A Side-by-Side Comparison

| Feature | CIJ (Continuous Inkjet) | Laser Coding |

|---|---|---|

| Initial investment | Lower | Higher |

| Operating costs | Medium (ink & solvent) | Low (no consumables) |

| Maintenance needs | Regular | Minimal |

| Mark permanence | Medium | High (permanent) |

| Material compatibility | Very broad | Requires material testing |

| Sustainability | Moderate | High |

| Coding speed | Very fast | Fast |

| Flexibility for message change | High | Medium |

So, Which One Is Right for You?

There’s no one-size-fits-all answer—it depends on your product type, environment, and business priorities.

Choose CIJ if:

- You produce at high speeds on varied surfaces

- You require frequent message changes

- You want a low upfront investment with proven flexibility

Choose Laser Coding if:

- You need permanent, tamper-resistant marks

- You want to reduce long-term operating costs

- Your brand requires high-resolution, eco-friendly marking

Final Thoughts

Choosing between CIJ and Laser Coding is a strategic decision. Both offer strong advantages depending on your specific needs.

At Mark-Xtra, we specialize in helping businesses identify the ideal coding solution for their production goals. Whether it’s Continuous Inkjet or Laser Coding, we provide top-tier technology, expert support, and local service to keep your line running smoothly.

📞 Contact us today to explore the best coding system for your business.

Mark-Xtra — More efficiency. More production.