In the pharmaceutical industry, every detail matters, and accurate information on medication packaging is essential for consumer safety. Coding and marking technologies play a crucial role in labeling and tracking pharmaceutical products. These tools enable products to be identified clearly and quickly, improving production process efficiency and reducing risks associated with dispensing errors.

In this article, we will explore how these technologies benefit the pharmaceutical sector and take a look at the most advanced coding and marking systems that are driving the industry forward.

Why Coding and Marking Technologies are Essential in the Pharmaceutical Sector

The primary goal of coding and marking in the pharmaceutical sector is to ensure that medications are accurately labeled and comply with safety regulations. These systems provide several key benefits:

- Product Traceability and Safety: Coding and marking systems allow precise identification of each batch of medication. This facilitates traceability, making it possible to track each product from manufacture to delivery, helping prevent fraud and counterfeiting of medications.

- Regulatory Compliance: Pharmaceutical regulations are stringent, requiring detailed information on packaging, such as expiration dates, batch numbers, and barcodes. Coding and marking systems ensure that medications meet these legal requirements, protecting both consumers and manufacturers from regulatory issues.

- Error Reduction: By automating the labeling and marking process, human errors are minimized. This is particularly important in an industry where a label error can have serious health consequences for consumers.

- Increased Production Efficiency: Coding and marking technologies enable smooth integration into production lines, automating the labeling process and accelerating production without compromising the quality of the marking.

- Sustainability and Waste Reduction: Certain technologies, such as laser marking, eliminate the need for inks and other materials, reducing waste and making the process more environmentally friendly.

With these benefits in mind, let’s explore the main coding and marking technologies used in the pharmaceutical industry and how each of them contributes to improving processes in this sector.

Main Coding and Marking Technologies in the Pharmaceutical Industry

There are several coding and marking technologies used for labeling medications. Each technology has particular characteristics suited to different production needs and packaging types.

1. Inkjet Printing

Continuous Inkjet (CIJ) printers are one of the most widely used technologies in the pharmaceutical industry due to their versatility and speed. These printers are ideal for marking products quickly and are compatible with a wide variety of materials.

- Benefits for the Pharmaceutical Industry: It allows for fast, economical marking on different types of packaging, from glass bottles to cardboard boxes. This is especially useful in high-volume production lines, where speed is essential to maintain efficiency.

2. Laser Coding

Laser marking is an advanced option that guarantees permanent, high-precision marking. This technology uses a laser to engrave directly onto the packaging, ensuring that the information does not fade over time or accidentally erase.

- Benefits for the Pharmaceutical Industry: Offers exceptional durability, ensuring that codes and expiration dates remain intact even in challenging conditions. Additionally, laser marking is fast and can be integrated into automated production lines, helping to reduce long-term costs and improve labeling quality.

3. Adhesive Labeling

Self-adhesive labeling involves applying a printed label to the medication packaging. Although it can be a more expensive solution due to the label cost, it is ideal for products requiring extensive visible information, such as usage warnings or additional ingredients.

- Benefits for the Pharmaceutical Industry: Allows for detailed information to be visibly included on the packaging, with customization options to add QR codes or barcodes that facilitate traceability.

Coding and Marking Machines for the Pharmaceutical Industry

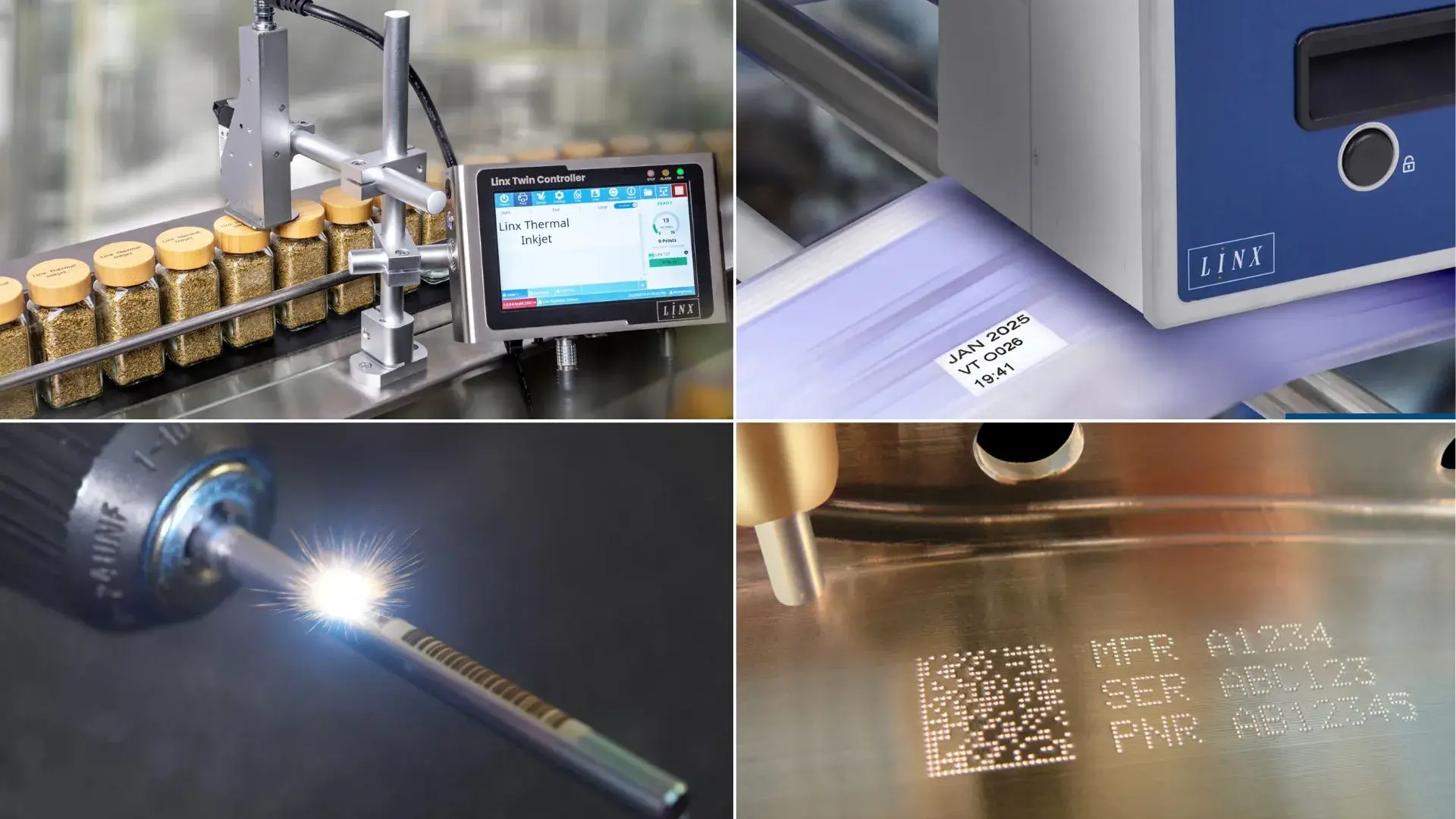

When it comes to selecting coding and marking machines for the pharmaceutical sector, it’s essential to choose reliable, high-precision options that ensure quality and durability. Linx, a recognized brand in this sector, offers two machines that stand out for their benefits to the pharmaceutical industry: the continuous inkjet (CIJ) printer and the laser coder. Below are the features of each:

Linx CIJ Coders

Linx continuous inkjet printers (CIJ) are specifically designed for high-speed product coding. These printers enable printing of details like expiration dates and batch numbers on various materials, which is essential for meeting regulatory requirements in the industry.

- Key Features:

- Ideal for printing on different types of substrates, such as glass, plastic, and cardboard.

- Industrial design minimizes ink waste, ensuring economical marking.

- Easy integration into automated production lines, facilitating use in high-speed environments.

Linx Laser Coders

Linx laser coders are a reliable, versatile option for those seeking permanent, high-quality marking on pharmaceutical products. These lasers allow for precise microprinting, ideal for anti-counterfeiting measures and for marking codes directly on capsules or tablets.

- Key Features:

- Provides permanent marking that withstands wear, essential for product safety.

- Capable of printing small-sized codes (microcodes) for anti-counterfeiting applications.

- Low operational cost, as it doesn’t use consumables like inks or labels.

Both Linx technologies represent high-quality solutions that benefit the pharmaceutical industry by improving precision and reducing the margin of error in product marking.

Conclusion

Coding and marking technologies are essential for safety and efficiency in the pharmaceutical industry. From ensuring each package is correctly identified to complying with strict regulations, these solutions ensure that medications reach consumers with the necessary information for safe use.

If you’re looking to enhance your pharmaceutical packaging with cutting-edge coding and marking technologies, Mark Xtra is here to help. Our expertise in packaging solutions and advanced marking systems ensures your products are accurately labeled, traceable, and compliant with industry regulations. Contact us today to learn more about how we can support your business needs!