Packaging plays a crucial role in protecting, handling, and marketing products across various industries. The type of packaging used depends on the product’s requirements at different stages of production, distribution, and consumer use. To better understand its functions, packaging can be divided into three main categories: primary, secondary, and tertiary packaging.

Primary Packaging

Primary packaging is the first layer of packaging that comes into direct contact with the product. It serves to contain, protect, and preserve the product while also being designed to attract and inform consumers. Its primary function is to ensure product integrity and prevent contamination. Examples of primary packaging include plastic or glass bottles for beverages, metal cans for food, plastic containers for pharmaceuticals, and snack pouches.

Common Coding Technologies for Primary Packaging

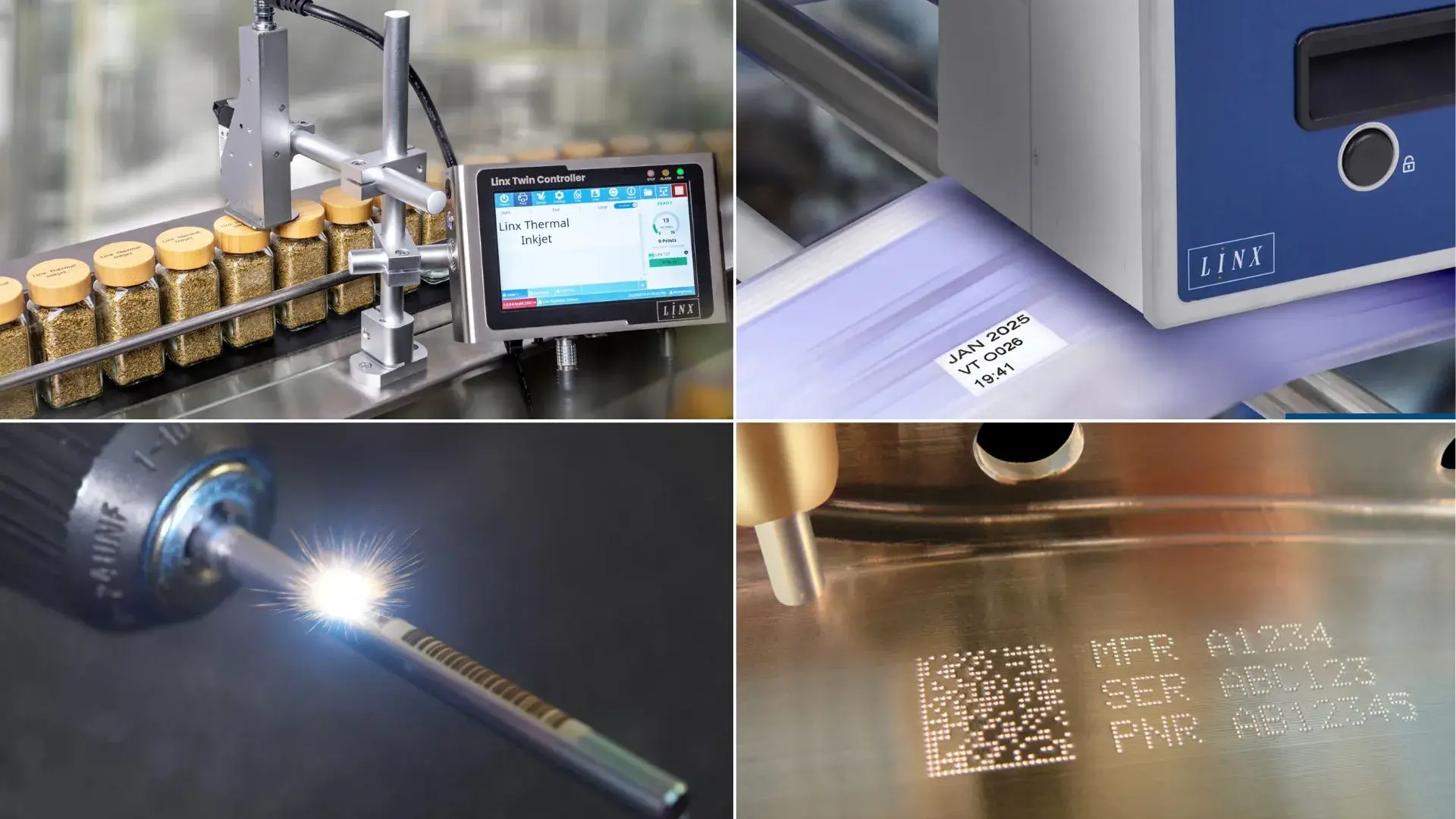

Since primary packaging is directly handled by consumers, its labeling must be resistant to friction and environmental factors. Technologies such as laser marking and inkjet printing are commonly used.

- Laser Marking: Engraves permanent and high-quality codes on materials like glass, metal, or plastic, ensuring readability even with frequent handling.

- Inkjet Printing: Includes continuous inkjet (CIJ) and thermal inkjet (TIJ) printing, used for expiration dates, batch numbers, and barcodes directly on packaging.

Secondary Packaging

Secondary packaging is used to group multiple primary packaging units into a single stock-keeping unit (SKU). It does not come into direct contact with the product but plays a key role in protecting the primary packaging, facilitating handling, and improving transportation efficiency. Additionally, it supports branding, marketing, and logistics. Examples include cardboard boxes holding multiple cereal packs or shrink-wrapped beverage trays.

Common Coding Technologies for Secondary Packaging

Secondary packaging requires clear, consistent labeling to aid in inventory and distribution. Common technologies include:

- Inkjet-Printed Barcodes or Print-and-Apply Labels: Used for SKU identification and warehouse tracking.

- RFID (Radio Frequency Identification): Increasingly used for real-time inventory management and tracking during shipments.

Tertiary Packaging

Tertiary packaging, also known as bulk or transit packaging, is designed for the storage and transportation of large quantities of products. It groups multiple secondary packages into large, manageable units to ensure secure transport. This packaging type is crucial for protecting goods during long-distance shipping and large-scale distribution. Examples include palletized products wrapped in stretch film or large shipping containers holding multiple smaller packages.

Common Coding Technologies for Tertiary Packaging

Tertiary packaging must accommodate large sizes and complex storage environments. Common marking technologies include:

- Thermal Transfer Overprinting (TTO) or Large-Scale Barcodes & QR Codes: Used for bulk inventory management and supply chain tracking.

- Inkjet Printing for Stretch Wrap & Palletization: Ensures secure packaging and facilitates bulk transportation tracking.

Why is Packaging Coding and Marking Important?

The technologies used for coding and marking packaging play a vital role in product identification, traceability, and overall logistical efficiency. Here’s why they are essential:

- Regulatory Compliance: Many industries, particularly food and pharmaceuticals, require product information, batch numbers, and expiration dates to meet regulatory standards.

- Traceability and Safety: Packaging codes, such as barcodes and QR codes, allow manufacturers, retailers, and consumers to track a product’s journey from production to consumption. Clearly marked packaging ensures quick identification in case of recalls.

- Logistics and Efficiency: Proper coding enhances inventory management, order fulfillment, and warehouse tracking, which is crucial for large-scale distribution requiring real-time monitoring.

- Branding and Marketing: Codes and markings on packaging can serve as branding tools. Unique codes can be used for consumer engagement, loyalty programs, or promotional campaigns.

- Cost Reduction and Error Minimization: Clear and accurate coding reduces human errors in packaging and shipping, minimizing returns and damage during transport. Efficient labeling speeds up supply chain processes, lowering costs.

Conclusion

In the modern supply chain, primary, secondary, and tertiary packaging each serve a unique role. From ensuring product safety to enabling efficient transportation, these packaging layers play a crucial part in logistics, branding, and compliance. Additionally, advanced coding and marking technologies—such as inkjet printing, barcode labeling, and RFID systems—are essential for regulatory compliance, inventory management, and product traceability.

For businesses looking to optimize their packaging and coding processes, Mark Xtra Coding and Marking Solutions provides reliable and innovative marking technologies tailored to various industries. Ensure your products meet quality standards and streamline your supply chain with Mark Xtra’s expertise in coding and marking solutions.

🔹 Need high-quality packaging marking solutions? Contact Mark Xtra today!