In today’s world, ensuring the safety and quality of products is a priority for any industry. Among the most essential equipment in this process is the date coder, a fundamental tool that ensures consumers have clear and accurate information about the shelf life of the products they purchase.

What is a date coder and what is it used for?

A date coder is a machine used to print key information on products, such as the manufacturing date, expiration date, and batch numbers. This information is vital for quality control, allowing both companies and consumers to verify the validity and safety of products.

Industries such as food, pharmaceuticals, and cleaning products use date coders to comply with safety regulations and to avoid issues related to the sale of expired products or incorrect information.

Types of date coders in the market

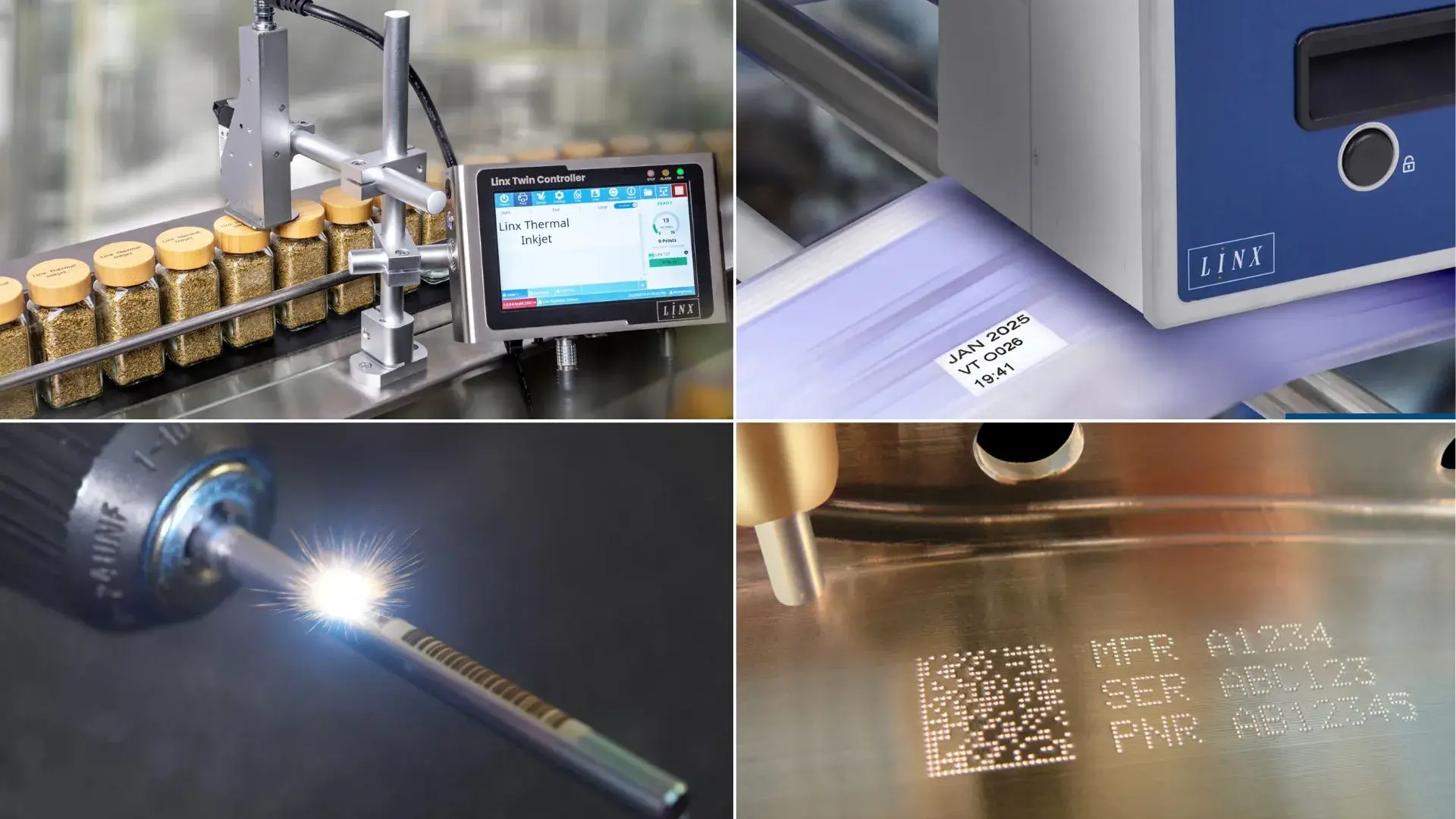

There are different types of date coders that adapt to the specific needs of each industry. Here are some of the most commonly used:

- Continuous Inkjet Date Coders (CIJ): Ideal for fast production lines, allowing printing on a wide variety of surfaces.

- Laser Date Coders: These use laser technology to mark information directly on the product or packaging without the need for ink. They are highly durable and provide precise printing.

- Thermal Transfer Date Coders: These work by using heat to transfer ink onto the product. They are commonly used for printing on labels and flexible packaging.

Advantages of using a date coder in your business

Incorporating a date coder into production processes offers numerous advantages. Among the main ones are:

- Precision and Clarity: A date coder ensures that information about expiration dates and other details is printed clearly and accurately, which is crucial to avoid errors that could compromise consumer safety.

- Regulatory Compliance: In many countries, it is mandatory for products to have visible expiration dates. A date coder facilitates compliance with these regulations and reduces legal risks.

- Production Efficiency: With a date coder, companies can automate the product marking process, resulting in increased operational efficiency and reduced costs.

Date coders as a key to success

A date coder is not only an essential tool for ensuring safety and quality control in production, but also an investment that improves operational efficiency and ensures compliance with regulations. In an increasingly competitive market, having the right date coder is essential for any company that wants to protect the integrity of its products and the trust of its consumers.

At Mark Xtra, we specialize in providing high-quality coding and marking solutions to ensure your products are always clearly and accurately identified, even in the most challenging conditions. If you’re looking to improve your production line’s efficiency and ensure your products meet the highest safety and quality standards, contact Mark Xtra today and discover how we can transform your industrial processes!