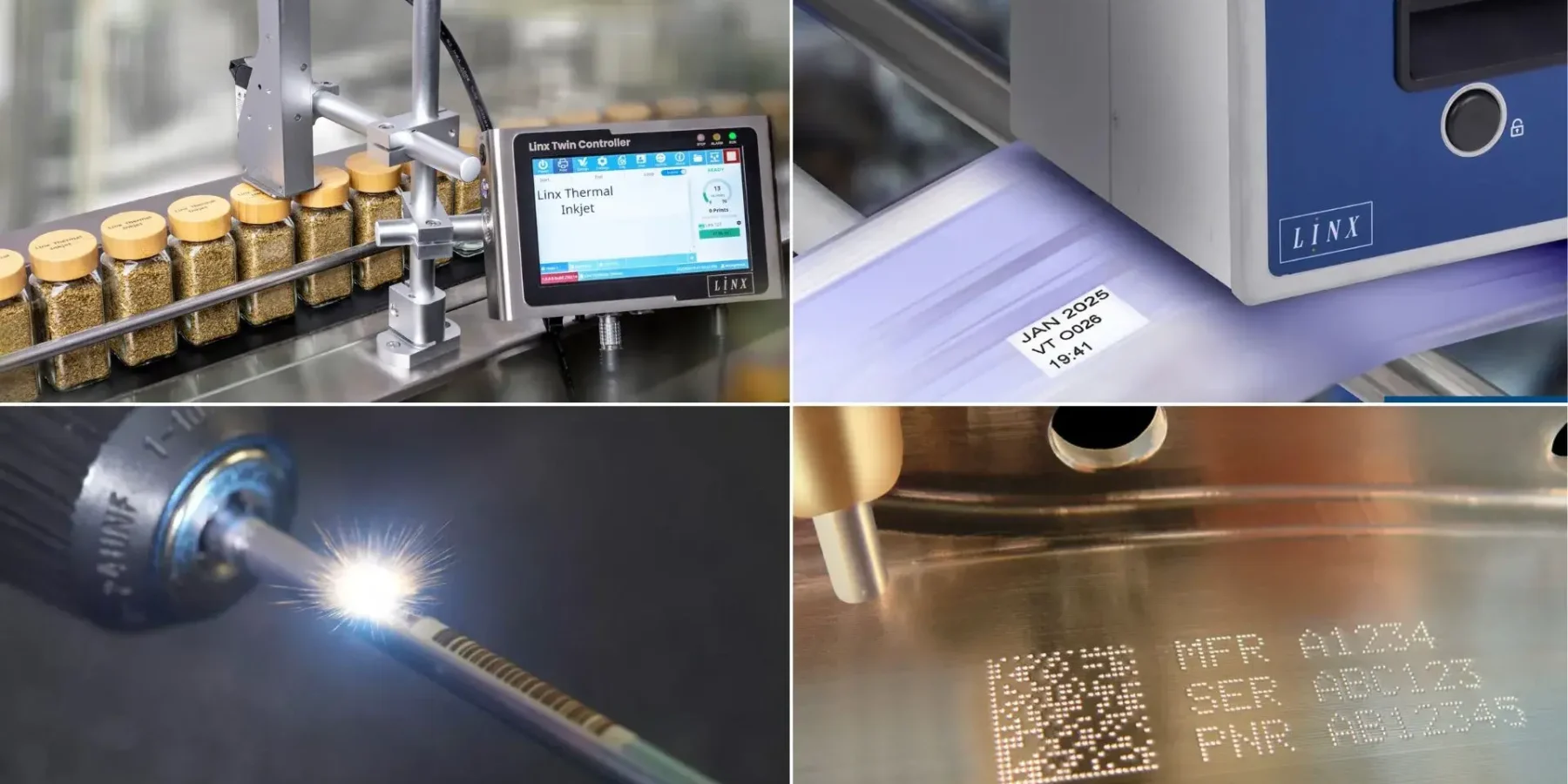

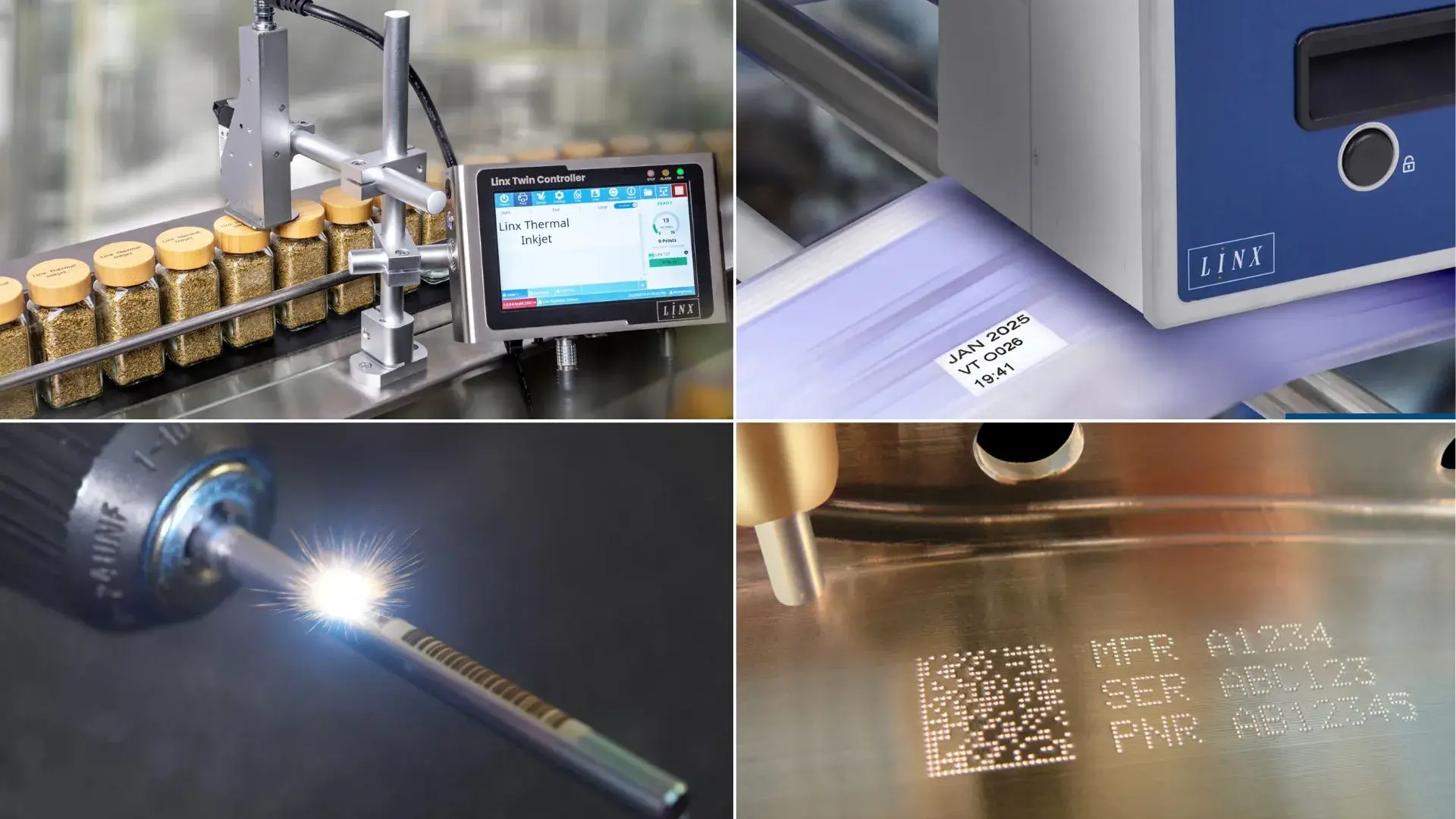

In modern manufacturing and packaging, coding and marking technologies play a crucial role in product identification, traceability, and compliance with industry regulations. From expiry dates and batch codes to barcodes and logos, the right technology ensures that information is applied clearly, accurately, and reliably.

The primary types of coding and marking technologies include Inkjet Printing, Laser Marking, Thermal Transfer Overprinting (TTO), and Label Print & Apply Systems. Each method offers unique advantages depending on the application, substrate, and production environment.

Let’s take a closer look at each:

1. Inkjet Printing

Inkjet technologies are among the most versatile solutions, capable of printing on a wide range of surfaces, from packaging film to glass bottles.

Continuous Inkjet (CIJ):

CIJ uses a continuous stream of ink droplets to print characters on products, even at high speeds. It works well on curved or uneven surfaces such as bottles, cans, glass, plastic, and metal, making it ideal for fast-moving production lines.

Thermal Inkjet (TIJ):

TIJ relies on disposable ink cartridges that eject ink using heat. Known for high-resolution and sharp prints, TIJ is best suited for small characters, barcodes, and logos on packaging materials like cartons and labels.

2. Laser Marking

Laser coders use a highly focused laser beam to etch or ablate material surfaces, producing permanent, tamper-proof marks. This non-contact method delivers excellent precision and is widely used for coding on plastics, glass, ceramics, and metals.

Key benefits include:

- Permanent marking resistant to wear and fading.

- Low consumable costs since no inks or ribbons are required.

- High-quality traceability and branding.

3. Thermal Transfer Overprinting (TTO)

TTO uses a heated printhead to transfer ink from a ribbon onto flexible packaging materials, such as pouches or films. It is commonly applied in the food, beverage, and pharmaceutical industries, where high-quality, durable codes are essential.

Advantages include:

- High-resolution prints.

- Instant drying with strong adhesion.

- Ideal for variable data such as expiration dates, batch codes, and barcodes.

4. Label Print & Apply Systems

Automated labelers either print labels on demand or use pre-printed labels, which are then automatically applied to products, boxes, or pallets.

This technology is especially useful in logistics, e-commerce, and warehousing, where labels often contain barcodes, QR codes, and shipping information. Labeling systems improve efficiency, reduce errors, and ensure consistent product identification.

5. Dot Peen Marking (Additional Technology)

Dot peen marking is a direct part marking technology that uses a stylus to create indented marks on metal or hard surfaces. It is widely used in the automotive, aerospace, and heavy machinery sectors, where permanent and durable codes are required for long-term traceability.

Benefits:

- Permanent, robust marking resistant to wear and extreme conditions.

- Capable of marking serial numbers, logos, and DataMatrix codes.

- Ideal for parts subject to harsh environments.

Choosing the right coding and marking technology depends on your production environment, product material, and specific industry requirements. From flexible packaging to industrial-grade components, these technologies ensure compliance, enhance traceability, and strengthen brand visibility.

Looking for the best coding and marking solutions in Angola?

At Mark-Xtra, we provide cutting-edge technologies—from inkjet and laser systems to thermal transfer and labeling solutions—tailored to meet your industry’s needs.

Contact us today to optimize your production line with reliable and innovative marking solutions!