In today’s fast-paced and highly regulated manufacturing environment, packaging coding is not just a compliance requirement—it’s a strategic element of quality control, traceability, and brand reputation.

From small-scale production lines to fully automated industrial systems, accurate and reliable coding ensures that every product is properly identified, tracked, and ready for market. But why exactly is packaging coding so important?

Let’s break it down.

1. Traceability: Track Every Step of the Product Journey

In industries such as food, beverages, pharmaceuticals, and cosmetics, being able to trace a product’s origin and destination is essential. Coding each package with lot numbers, manufacturing dates, and batch codes enables companies to:

- Respond quickly in case of a product recall.

- Identify production issues more efficiently.

- Ensure transparency across the supply chain.

Without traceability, a small mistake can turn into a costly crisis. With proper packaging coding, you maintain control and accountability at every stage.

2. Consumer Safety: Inform and Protect Your Customers

When a customer picks up a product, they expect clear information about its shelf life and origin. Packaging coding ensures vital information is always visible, such as:

- Expiration dates

- Lot and batch numbers

- Manufacturing time and place

This isn’t just about convenience—it’s about protecting public health and meeting your ethical responsibilities as a manufacturer.

3. Regulatory Compliance: Meet Industry Standards with Confidence

Each industry has strict regulations that govern how products should be labeled and coded. Failing to comply can lead to fines, bans, or even product seizures. Proper packaging coding allows companies to:

- Meet national and international standards

- Facilitate customs clearance and distribution

- Avoid costly compliance issues

Whether you’re targeting local markets or exporting globally, your coding process must meet all legal requirements.

4. Brand Credibility: Build Trust Through Professionalism

Your packaging is often the first impression a customer has of your product. Poor or missing coding can make even the best product appear unprofessional or counterfeit.

Consistent and high-quality printing reflects the seriousness of your quality control process and enhances your brand image. Customers trust products that are clearly and correctly labeled.

5. Operational Efficiency: Streamline Inventory and Logistics

Internally, packaging coding helps organize your stock, reduce manual errors, and improve logistics. With proper codes in place, you can:

- Improve warehouse management

- Implement FIFO (First-In, First-Out) systems

- Automate sorting and inventory tracking

Efficient coding leads to efficient operations—saving time, reducing costs, and increasing productivity.

Mark Xtra: Your Partner in Industrial Coding Excellence

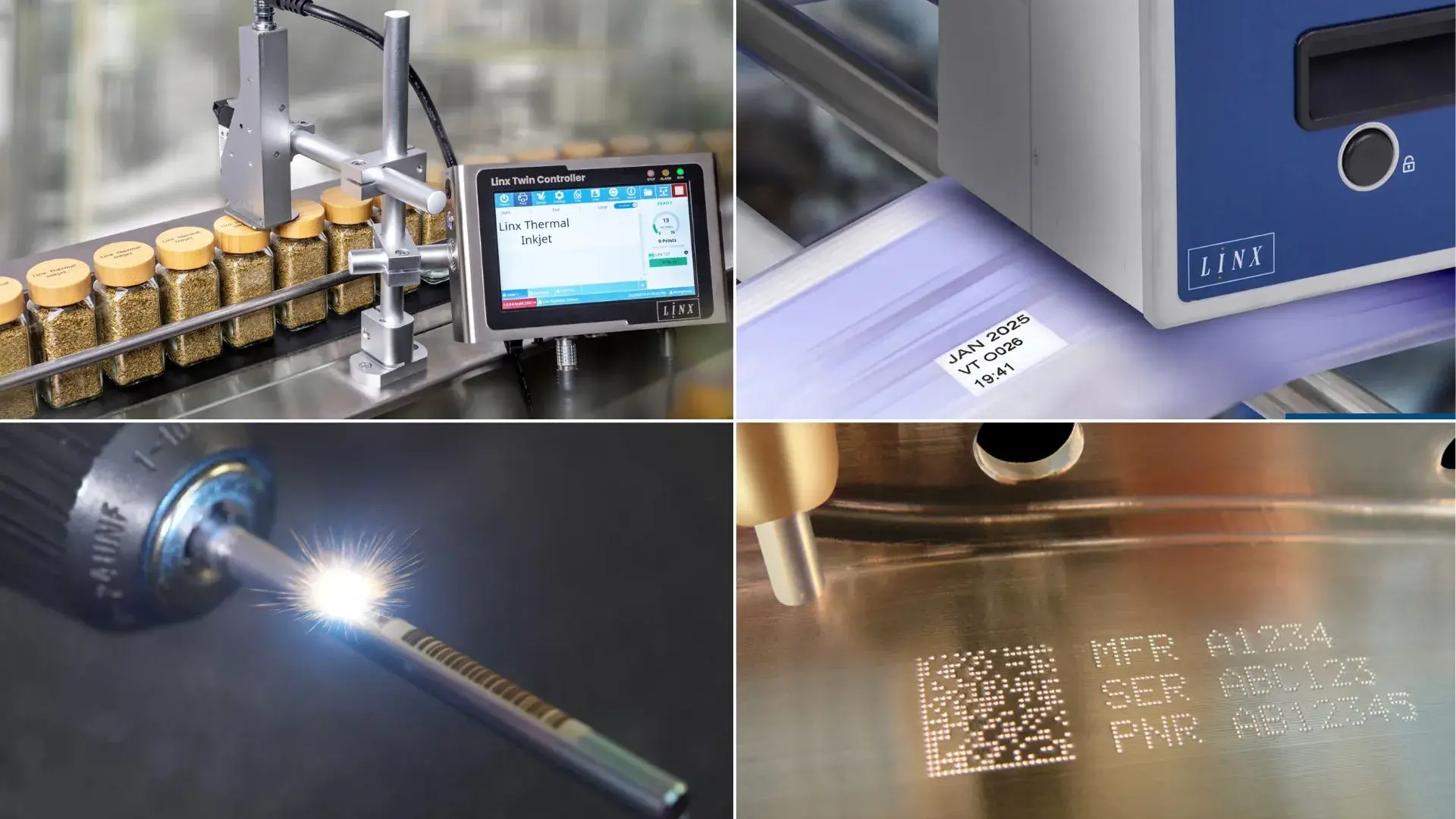

At Mark Xtra Coding and Marking Solutions, we specialize in helping companies implement the right packaging coding solutions for their specific needs. From high-speed CIJ printers for large production lines to compact TIJ systems for batch printing, we offer:

- Advanced coding equipment

- Industry-specific consultation

- Ongoing technical support

- Customized integration for your production line

Our mission is simple: to help you code smarter, faster, and with complete peace of mind.

Contact us today to discover which printer fits your packaging and production needs. At Mark Xtra, we don’t just sell machines—we support your success.